| Origin Country | China |

| Warranty Time | 12 Months |

| Customization | Support Customization |

| Different Payments | T/T,Trade Assurance, Western Union |

Description

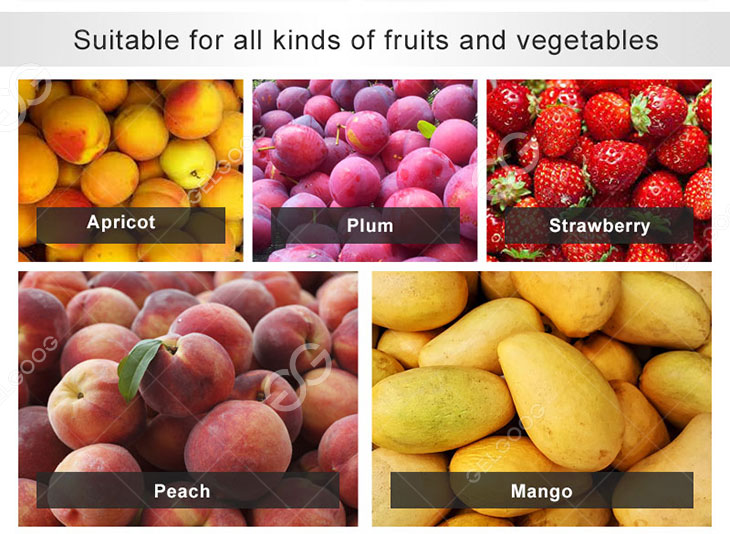

The mango pulp machine first cuts the mango fruits and other fruits into segments by the rotary cutter at the feeding port, and then chops them into small segments by the high-speed rotating hammer knife to make pulp at one time. The mango pulp extraction machine is an ideal machine for making mango puree jam, fruit juice and vegetable juice, and is suitable for pulping a variety of fresh fruits and vegetables.

Such as: beating and removing dregs of stone fruits (mango, peach, apricot, etc.), berries (kiwi fruit, strawberry) and pome fruit (apple, pear, etc.). The mango pulp produced has the advantages of long storage time, small loss of nutrients and good eating taste.

Mango Pulp Machine Advantages

Clean and hygienic

The mango pulp machine parts in contact with mangoes are made of high-quality stainless steel, which is in line with food hygiene

Automatic separation

The mango pulp residue is automatically separated, it can combine in the mango pulp processing plant or by a single mango pulp making machine

Stable function

The first step is to remove the pit, and the second step is to beat the mango to realize the automatic separation of mango core, mango skin and mango pomace.

Mango Pulp Extraction Machine Parameter

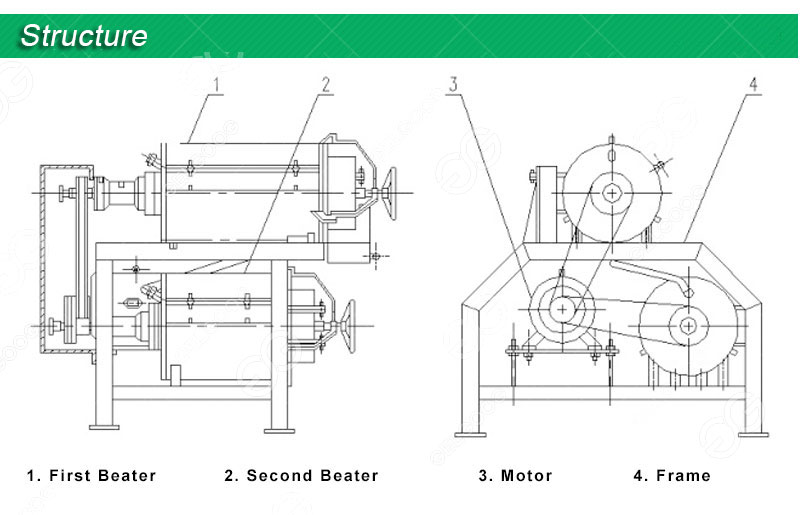

Mango Pulp Making Machine Structure

Cylinder sieve: The cylinder body is punched with a stainless steel plate with a thickness of 0.35~1.20mm and bent into a country, welded after the circle, with reinforcement rings welded on both sides, or two semi-circular bodies are connected by screws to form a cylinder body, which is placed horizontally in inside the case.

Shaft: Mango pulp making machine equipped with two scrapers that move the material to the crushing blade, screw propeller, and scrape the material, the scraper is connected with the holder on the shaft with bolts, and the adjustment bolt can adjust the distance between the scraper and the screen wall . Symmetrically installed on the C side of the shaft, there is an included angle with the shaft – the lead angle.

Unloading hopper Collecting hopper, frame, transmission system.

Mango Pulp Grinding Degree Affect Factors

(1) The nature of the mango and other fruits itself

(2) Diameter of sieve hole: 0.4~1.5mm, different raw materials and different processing requirements can change the sieve cylinder with different apertures.

(3) The percentage of the total area of sieve holes in the total area of the sieve cylinder: 50%

(4) Lead angle 1.52.0 (with 3°)

(5) Distance between stick and inner wall: 1~4mm

(6) The speed of the shaft

Main adjustments during use (6), (5), (4)