Fully Automatic Dried Mango Processing Machine

The dried mango processing machine includes mango washing, air drying, peeling, slicing, drying, packaging, and the mango drying process simulates the principle of natural air drying and adopts a low temperature and slow dehydration process. It has flavor and extends the shelf life of mangoes.

Dried Mango Production And Drying Process

Mango selection → cleaning → peeling → slicing → color protection → bubble sugar (primary sugar soaking) → vacuuming → cooking → bubble sugar (secondary sugar soaking) → plate placement → drying → softening →Packaging →Storage

Material selection: Choose mangoes with small pits and thick flesh. The mango ripeness should be 8 to 9. If the mango maturity is too low, the color and flavor of the mango will be poor, and if it is too ripe, it will be easy to rot.

Washing: Wash mangoes by hand or in a washing machine. After washing, allow to drain.

Peeling: The rind must be removed, because the tannins are contained in the causal rind. If it is not peeled, browning will easily occur during processing, which will affect the color of the dried mango.

Slicing: The peeled mango is sliced longitudinally with a sharp blade, with a thickness of about 8-10 mm.

Color protection: The cut mango slices should be immediately soaked in sugar water with color protection solution (no need to use sulfur dioxide as a color protection agent to achieve the purpose of color preservation, flavor preservation, and antisepsis).

First dip in sugar: add white sugar during the color protection of mango slices, one layer of mango slices and one layer of white sugar, and the top layer should be covered with a layer of white sugar. The white sugar is marinated for 15-25 hours, and the sugar content is 20-30 degrees after equilibrium.

Vacuuming: The mango pulp marinated in sugar is sent to a vacuum machine for vacuuming, and the sugar water is extracted.

Cooking: Take the vacuumed mango pulp, add sugar, maltose and ethyl maltol and cook it in a pot. The concentration of sugar water should reach minute 45% to 60%.

Second dip in sugar: Scoop out the boiled mango pulp and concentrated sugar juice into a soaking bucket, add sugar to soak, and filter to obtain the second marinated mango pulp and the second marinated sugar water;

Placing: Carefully take out the mango slices and place them on the drying tray one by one. Lay them flat and do not stack them.

Drying: Start the air energy heat pump dryer and set the mango drying parameters:

Drying stage 1: 65℃-68℃, high temperature baking for 5 hours;

Drying stage 2: 60-62 ℃, the mango slices are continuously dried for 5 hours;

Drying stage three: 55-58 ℃, while increasing the humidity, drying for about 5 hours;

Drying stage four: the temperature drops to 50 ℃, the drying time is about 5 hours, and the drying is finished.

When the time runs out, the dried mango can be guaranteed to be dried.

Softening: Dried mangoes generally have a final moisture content of about 15%-18%. After reaching the drying requirements, take the dried mangoes out of the air energy drying room, put them in an airtight container, and soften them for 2-3 hours.

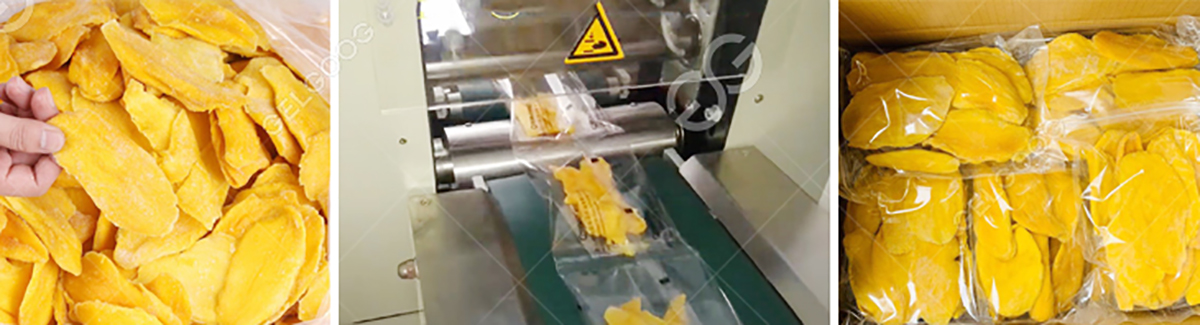

Packaging: After the dried mango is softened, the texture is soft and convenient for packaging. Generally, it is packaged in a high-barrier transparent composite film bag.

Storage: Put the dried mango in a packaging bag, pay attention to storage at low temperature and away from light. Dried mangoes are prone to oxidative deterioration or browning during storage, so it is best to keep them refrigerated.

Dried Mango Processing Machine Parameter

Item | Model | Capacity(kg/h) | Power |

Mango Washing Machine | GGXM1200 | 800 kg/h | 1.5 kw |

Mango Peeling Machine | GG-GW-500 | 500-1200 pcs/h | 0.8kw |

Mango Slicing Machine | GG-800 | 500-800kg | 1hp |

Mango Drying Machine | GG-7P | 300-700 | 380/3/50 |

Dried Mango Packing Machine | GG-LK720 | 10-50bags/min | 4kw/220v 50-60Hz |

Share This Post,Choose Your Platform!