New Design IQF Frozen Mango Processing Plant

The frozen mango processing plant can keep perishable mangoes fresh for the longest time, and maintain the original quality, flavor and color of mangoes to the greatest extent. And it can be processed into high-quality mango food favored by all kinds of consumers in one step. Frozen mango chunks are one of the processed mango products. It is not only the consumption of mangoes by consumers in various regions and seasons, but also can be used as dessert raw materials for high-end hotels and restaurants. It is very popular in the international market. One of the frozen fruit and vegetable products.

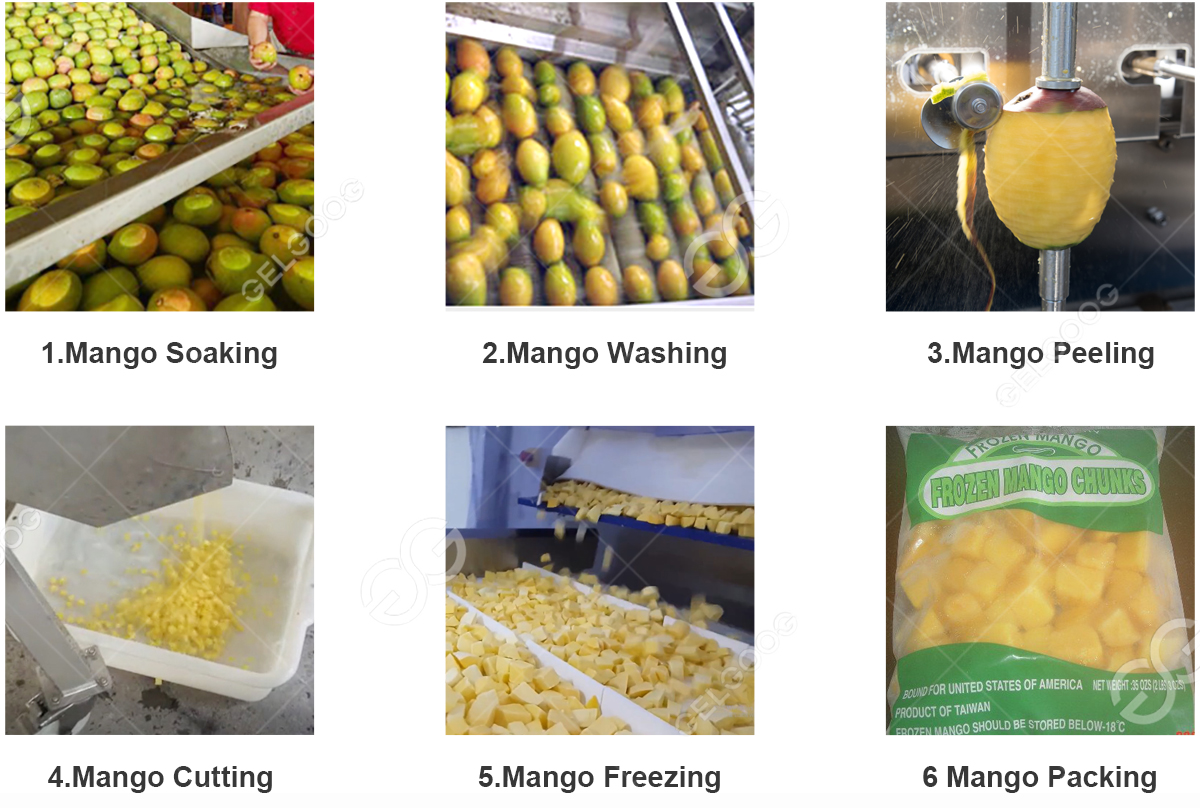

IQF Diced Mango Working Process

Raw materials → mango rough washing → mango peeling and pitting → mango washing → mango dicing/slicing → mango quick-freezing → frozen mango packaging → metal detection → storage

The receiving area must be clean, well ventilated and free of insects, rodents or other animals. It is not recommended to leave mangoes for too long before processing to avoid spoilage. Pick ripe mangoes that are free from pests and diseases.

Washing, washing pits should be filled with water containing 15 ppm chlorine to reduce microbial load and impurities in the fruit. Do a second wash with clean water to remove residual chlorine.

For peeling and pitting, a semi-automatic mango peeling and cutting machine is used. Only manual feeding is required to achieve automatic peeling and semi-cutting of mangoes. Mango pits require manual removal.

Blanching, which is done to inactivate enzymes, remove air from the mango fruit tissue, remove odors and aromas, fix the fruit color and soften the tissue for further pulping.

Slicing/dicing, according to the different requirements for the shape of the frozen mango products, we can configure a professional mango dicing machine/mango slicing machine, which can quickly realize the processing of mango dicing/slicing, saving time and improving efficiency for the processing of quick-frozen mangoes .

For quick freezing, a fluidized monomer quick-freezing machine is used to make the mango diced/slices on the mesh belt evenly. Under the action of strong cold air from bottom to top, the mango diced/slices show a “fluidized” movement. and is quickly frozen during this exercise. Due to the strong interaction between the strong cold airflow and the mango diced/slices, the heat transfer in the mango diced/sliced layer is very fast, so that the mango diced/slices can quickly complete the three stages of cooling, surface freezing, and deep freezing in a short time. Thereby, the purpose of quick freezing of the food monomer is achieved.

For packaging, the multi-head weighing packaging machine is used to automatically complete the process of feeding, measuring, filling and bag making, printing the date, and outputting the finished quick-frozen mango.

frozen mango processing plant Advantages

1 Reduce loss and material leakage during mango processing.

2 Minimize the number of workers in the mango quick-freezing production line.

3 The mango quick-freezing production line equipment is easy to clean and maintain after use.

4 Equipment operability, reliability, and energy consumption should be optimized as much as possible.

5 Greatly improve the degree of automation and mechanization in the processing of quick-frozen mangoes.

6 Improve the quick-freezing efficiency of mangoes and improve the processing quality of quick-frozen mangoes.

7 The frozen mango processing line appearance and materials are exquisite,adopt the new technology in the frozen mango production process.

Frozen Mango Processing Line Parameter

Item | Model | Capacity(kg/h) | Power |

Mango Washing Machine | GGXM1200 | 800 kg/h | 1.5 kw |

Mango Peeling Machine | GG-GW-500 | 500-1200 pcs/h | 0.8kw |

Mango Slicing Machine | GG-800 | 500-800kg | 1hp |

Mango Frozen Machine | GG-IQF-500 | 500 | 24kw |

Frozen Mango Packing Machine | GG-LK720 | 10-50bags/min | 4kw/220v 50-60Hz |

Share This Post,Choose Your Platform!