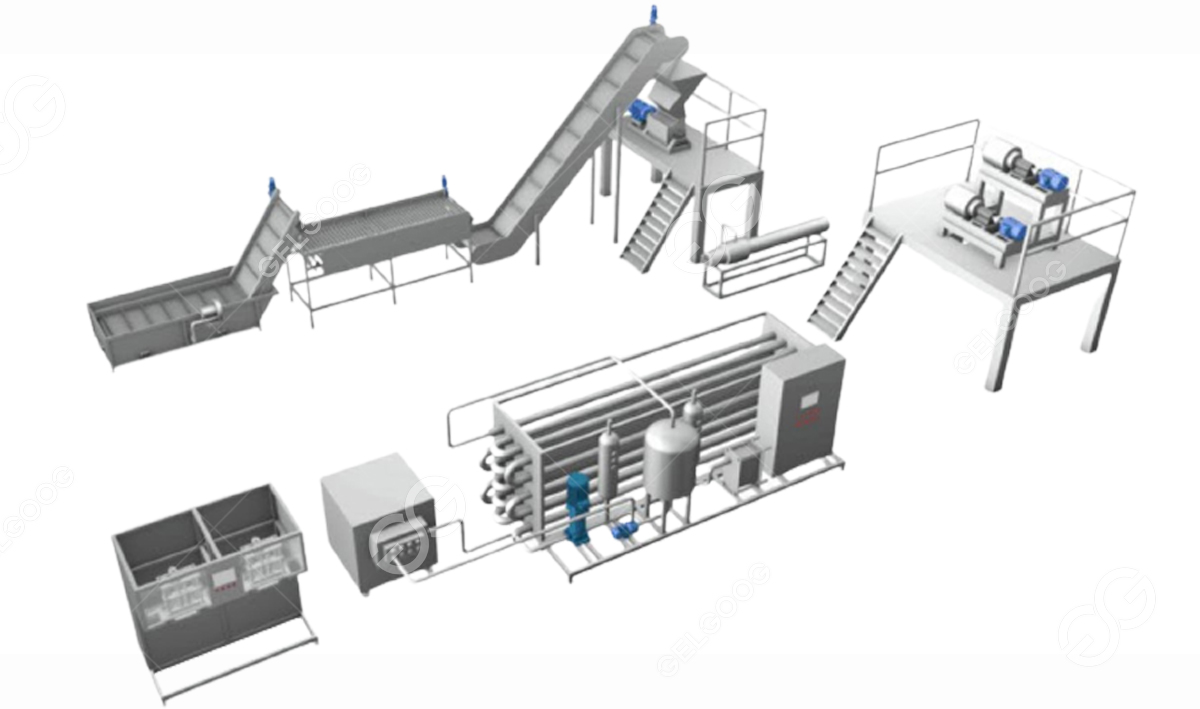

Industrial Mango Fruit Pulp Processing Machinery Plant

The mango pulp processing machinery is to process fresh mangoes into clear and turbid juice through the processes of cleaning, beating (peeling and cored), crushing, juicing, enzymatic hydrolysis, membrane filtration, concentration, sterilization, filling, etc. And packaged in various containers such as roof bags, Tetra Pak bags, aseptic bags, aseptic vats, etc., to achieve the purpose of cold chain or normal temperature sales.

Mango Pulp Processing Flow

Process flow of mango pulp/ juice complete processing production line: raw material → brush cleaning machine → fruit sorting machine → bubble cleaning machine → mango beater → vibrating screen → temporary storage tank → screw pump → enzyme killer → temporary storage tank → vacuum degasser → screw pump → sterilizer → finished product tank → to the next process.

Mango selecting

The selected mangoes should be free of pests, no mechanical damage, mature stage, uniform color and texture, minimum soluble solids at 13° Brix, pH 3.5 to 4.0.

The receiving area must be clean, well ventilated and free of insects, rodents or other animals. It is not recommended to store mangoes too long before processing to avoid spoilage.

Mango washing

15 ppm chlorine can be added to the pool of the mango hopper washer and stirred well to reduce the microbial load and impurities in the mangoes. Perform a second wash with a bubble washer filled with clean water to remove residual chlorine.

Mango pre-heating

This is done to inactivate enzymes, remove air within the mango tissue, remove odors and aromas, fix fruit color and soften the tissue for further pulping.

Mango pulping

Pass the medium mango peel through a fine mesh to remove unwanted particles. After beating, a smooth puree is obtained. The recommended mesh size is 0.5 mm. Coarse material is separated and properly disposed of during this process. The mango puree is transferred in the container to the kettle.

Heat treatment

Heat treatment in kettles to prevent chemical and microbial spoilage. In this treatment, mango pulp reaches 95°C for 10 minutes. Stir constantly.

Additives

Additives are recommended to extend the shelf life of the pulp. Commonly used additives include 0.39% citric acid to lower pH and prevent microbial growth and increase the effectiveness of preservatives such as sodium benzoate (0.5%).

To prevent discoloration, use 0.1% ascorbic acid as an antioxidant. Add the additive to the mango puree by dispersing in hot water or mango puree and stirring appropriately before the heat treatment is complete (about 5 minutes ago). The final product should have a Brix of 13° and a pH between 3.4 and 3.5.

Mango Pulp/juice Packaging

The mango puree is packaged in a plastic container when hot, immediately sealed and turned over so that the inside of the lid is in contact with the hot product. All packaging materials must be cleaned before use.

Packaged Mango Pulp/juice Cool down

The thermal vessel is cooled with fresh water at the lowest temperature achievable. After cooling, the lid should be checked for closure. Finally, clean and label the container before sending it to a fresh, clean storage location.

Mango Pulp Processing Machinery Features

1.It can handle fruits with similar characteristics

2.The treatment capacity ranges from 60 tons / day to 1500 tons / day.

3.Mango pulp yield can be effectively improved by using mango efficient peeling machine.

4.It can realize PLC control in the whole production process, save labor and facilitate production management.

5.Vacuum concentration at low temperature can retain flavor and nutrients to the maximum extent and save energy.

6.Aseptic tube sterilization and aseptic barrel filling can produce high quality aseptic juice products.

7.Full automatic CIP cleaning ensures the food hygiene and safety requirements of the whole line equipment.

Mango Pulp Processing Plant Parameter

|

Item |

Quality(set) |

Power |

Dimension(MM) |

|

|

|

(KW) |

|

|

Brush Roller Washer |

1 |

1.5 |

2300×900×1600 |

|

Mango Sorter |

1 |

0.75 |

3500×1000×1200 |

|

Bubble Washing Machine |

1 |

2.95 |

3000×1000×1800 |

|

Mango Pulp Machine |

1 |

4 |

1600×650×1500 |

|

Vibrating screen |

1 |

0.75 |

1000×900×1000 |

|

Temporary storage tank |

2 |

500L |

Φ1000×800 |

|

Screw pump |

2 |

1.5 |

1400×420×370 |

|

Enzyme Killer |

1 |

|

1500×615×1250 |

|

Vacuum Degasser |

1 |

2.2 |

1200×850×1800 |

|

Sterilizer |

1 |

|

1200×920×1650 |

|

Finished tank |

1 |

|

Φ1000×1200 |

Share This Post,Choose Your Platform!