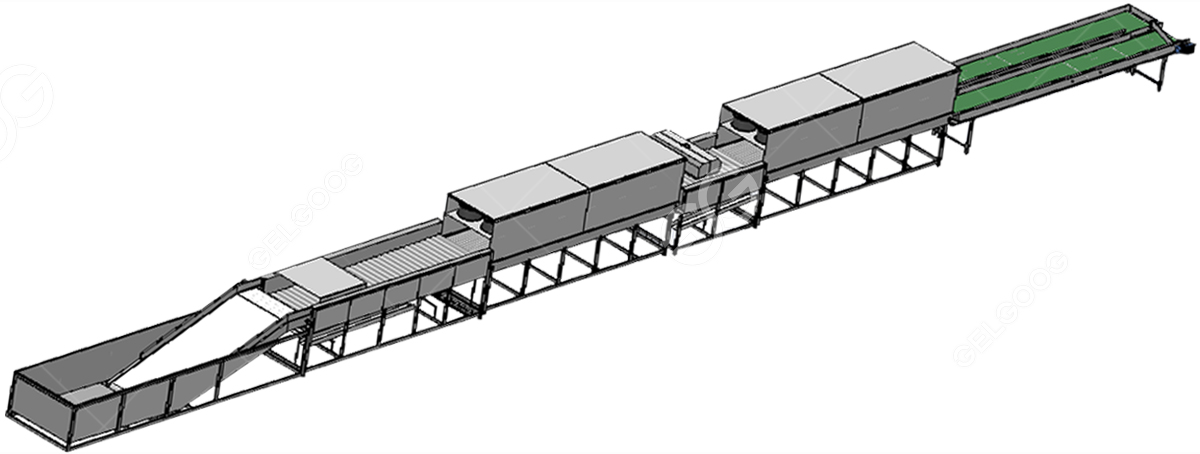

Mango Washing And Waxing Line

The mango washing and waxing line is composed of mango washing machine, blanching machine, air drying machine, picking machine, lifting conveyor, waxing machine, sorting machine and other mango processing equipment. The equipment is made of 304 food grade stainless steel, which is clean, hygienic and durable. Cleaning programs can be designed according to the different requirements of customers. The fruit cleaning, waxing, air-drying and grading line is suitable for the cleaning and processing of hard fruits, and the processing, preservation and sorting of oval fruits and vegetables such as navel oranges and citrus.

Mango Washing Waxing Process

The mango washing machine is used to clean fresh mangoes. The unique large pool is suitable for large batch cleaning. It can soak the mangoes and prevent the mangoes from bumping each other when poured into the pool.

Its features:

1. All made of high-quality 304 stainless steel, in line with international food industry standards

2. The large pool is suitable for large batch cleaning (large turnover basket)

3. High pressure bubbles imitate the principle of manual cleaning

4. The high-pressure spray section of the brush roller can remove stubborn stains and soil

5. According to the material characteristics, there are soft and hard brushes optional

6. Freely control the running speed through the inverter.

The mango waxing machine adopts a high-power liquid wax pump, which can continuously supply wax and can be freely adjusted according to the processing capacity requirements and the demand for wax volume of different fruits. The wax spray nozzle has a good atomization effect. Waxing is uniform, covering a large area, and there will be no occurrence of no wax or overlapping of wax layers. It is suitable for waxing and glazing of various fruits, such as apples, citrus, oranges, grapefruit, tangerines, etc., to make the fruit surface bright and bright, keep fresh, prevent moths, and improve the commodity value of fruits.

1. The whole machine is made of 304 stainless steel.

2. High power, easy to operate, labor-saving, labor-saving and so on.

The mango drying line uses a large air volume and low noise fan to dry the mango.The conveyor belt transport the dried mangoes to the next process. Its features:

1. Use the principle of high-pressure fan to dry, according to different materials, it is divided into natural air and hot air

2. The natural wind can effectively protect the color and quality of the mango itself

3. Hot air drying is suitable for mangoes that are resistant to high temperature and need to be dried later

4. Conveying mesh belt frequency conversion speed regulation to meet different materials

5. Multiple tumbling conveying and reverse wind design, thoroughly dry the residual water droplets on the mango surface

6. All made of high-quality 304 stainless steel, in line with international food industry standards

The mango sorting machine is mainly suitable for materials that can be slightly bumped, such as spherical and cylindrical. Its features:

1.All made of high-quality 304 stainless steel, in line with international food industry standards

2.Well-known brand electrical components and control systems

3.The sorting level is preset and cannot be increased but decreased

4.Breaking the traditional model that the size of each grade of the traditional grader cannot be changed, the machine can be easily adjusted to achieve changes in the range of each grade

5.Wide range of applications, suitable for spherical, cylindrical and other materials that can be slightly bumped

6.Freely control the running speed through the inverter

The mango picking machine is suitable for the selection and transportation of materials. The unqualified defective products are manually selected, the roots of the materials are cut off on the operation board, and the qualified products are automatically transported to the next process. Its features:

1.Manual sorting

2.Cut off the roots of the material on the operation panels on both sides

3.Qualified products are automatically transported to the next process through the conveyor belt

4.The conveyor belt is made of safe and environmentally friendly PVC material

5.The body is made of food grade 304 stainless steel, PVC conveyor belt

Mango Washing Waxing Machine Parameter

| Machine Name | Length(m) | Width(m) | Height(m) | Power |

| Soaking pool | 6.47 | 1.55 | 1.8 | 1.5KW |

| Lifting | 3.5 | 1.2 | 0.9 | 1.1KW |

| Brush type washing machine | 4.5 | 1.23 | 1.8 | 3KW |

| Air dryer | 5.05 | 1.28 | 2.04 | 1.1KW |

| Waxing machine | 2 | 1.3 | 1.7 | 1.5KW |

| Air dryer | 5.05 | 1.28 | 2.04 | 1.1KW |

| Conveyor | 6.07 | 0.6 | 1.1 | 0.55KW |

Mango Washing And Waxing Line Advantages

Reasonable design, compact and sturdy structure, beautiful appearance, light and durable.

Low power consumption, low noise, no damage to fruit, flexible movement and easy maintenance.

One mango processing line has multiple functions, wide application range, high sorting efficiency and simple operation.

Share This Post,Choose Your Platform!