At present, there are many mangoes on the market that use cold storage or quilts to ripe mango, and they all use high temperature to accelerate the ripening of mangoes. The ripening speed is fast enough, but is this really good? High temperature is not conducive to the formation of color and flavor, and the shelf life of mangoes ripened at high temperature is still short. I still recommend using appropriate temperature for ripening. The principle of mango ripening is similar to that of banana ripening. This article introduces the use of differential pressure Ripe library ripening mangoes.

how to tell if a mango is ripe?Factors affecting the ripening of mangoes

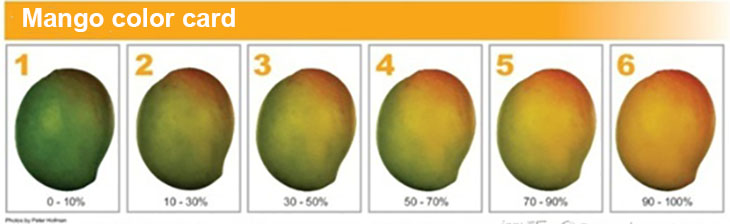

Mangoes must reach a certain degree of maturity, and the solids content should not be less than 14%. The higher the maturity of mangoes, the easier it is to ripen. The maturity can be comprehensively assessed by the appearance color, firmness and the color of the flesh of the fruit cut surface.

Different varieties of mangoes have different hardness, sugar content and pulp color at different stages. The following are some data of several mangoes

The picking time and storage conditions of mangoes are generally easy to ripen in the early stage of the production season, and the longer the storage period and the higher the storage temperature, the easier it is to ripen. Therefore, it is necessary to check the mangoes in the storage every day, and find that the mangoes that start to ripen need to be dealt with in time.

The storage temperature of mango is 10-12°C, and the pulp temperature is 10-14°C (different varieties have different low temperature tolerance). If the tolerance temperature of the variety cannot be determined, the storage temperature should not be lower than 12°C.

ripening control conditions

Temperature: It is recommended to control the temperature at room temperature, the temperature is 20-22 °C, and the temperature is controlled by the pulp, the temperature is 18-22 °C; the room temperature does not exceed 25 °C. If the temperature is too high, it is easy to cause uneven color change, which affects the formation of flavor substances, and the skin loses water to form wrinkles, which ultimately affects the shelf life performance.

Ethylene: Ethylene is treated for 24-72 hours according to the maturity (the ethylene may not be added after heat treatment), and the ethylene bottle is continuously injected, and the ethylene concentration is 10-20 ppm; if an ethylene generator is used, the ethylene generator is started every 6-8 hours, and the ethylene concentration Set it above 100ppm, or reasonably arrange the interval time and treatment concentration as needed, and inject ethylene when the pulp temperature rises to 20°C.

Non-industry people or consumers may doubt the safety of ethylene, but the author is very responsible to tell you that it is absolutely safe, and ethylene has been used for fruit post-ripening treatment for decades, and ethylene is used in the ripening process. It is just a catalytic effect, which accelerates the respiration of the fruit, and the fruit itself also produces ethylene gas during the ripening process.

Carbon dioxide concentration: the whole process concentration is controlled below 10000ppm (1% concentration), which can be set by the system, or controlled at time intervals.

Humidity: 85%

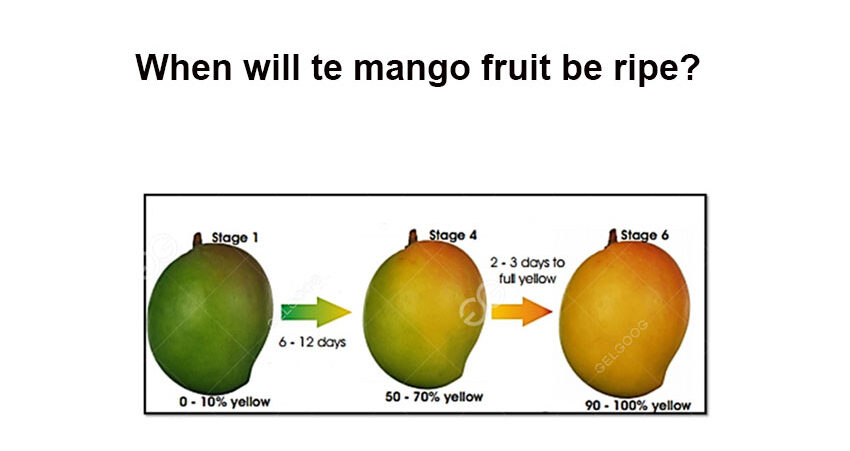

Ripening time: Generally 2-3 days according to the above treatment plan, the yellowness can reach 50%-70%.

How To Tell If A Mango Is Ripe

During the ripening process, the skin color of most mango varieties gradually changes from green to yellow, orange, red, or smudges/spots of these colors (the specific changes depend on the variety, such as Tainong mangoes turning golden yellow, Kate mangoes turning red and yellow, Guifei mangoes turning red and purple, etc.). The mango sorting machine is equipped with a high-resolution CCD/CMOS camera and a specific light source (such as LED white light or customized spectrum), which can accurately capture the overall color, color spot distribution, color uniformity and other visual information of each mango as it passes through the inspection area.

Problems with the ripening process

A.Mature too slowly

(1) The ripeness of green mangoes is not enough, even after ethylene treatment, the ripening is slow, so the ripeness of the fruit should be checked upon arrival.

(2) The temperature of the pulp is low. The lower the temperature of the pulp, the slower the ripening. It is necessary to monitor the temperature data of the ripening process every day and adjust it in time.

(3) Carbon dioxide concentration is higher than 10000ppm, carbon dioxide inhibition is mature, and the exhaust system needs to be checked regularly.

(4) If the injection of ethylene fails, check the failure of the ethylene bottle and the ethylene generator to ensure the treatment time and concentration of ethylene.

B.Uneven maturation

It is mainly manifested that the maturity of different positions of the unified pallet is inconsistent, and the maturity of different positions is different.

(1) The maturity of the fruit is different, and the fruit may come from different origins, varieties, orchards, picking time, and post-harvest transportation and storage conditions.

(2) The impact of fruit packaging: the gap rate of packaging is less than 5%, resulting in insufficient ventilation, so the heat generated by fruit respiration cannot be taken away, resulting in differences in the temperature of local pulp, fruit ripening faster or slower, and uneven color , The tightness of the inner packaging will also affect the temperature change difference.

(3) The ripening warehouse adopts a differential pressure system. If you do not pay attention to the excessive gaps between the goods when entering the warehouse, or the air duct is not well sealed, and the ventilation volume at different positions is not enough, it may also lead to uneven ripening.

(4) Without ethylene treatment, there is no ethylene involved in ripening, and the ripening process of different fruit individuals will be inconsistent only by the effect of endogenous ethylene.

C.Uneven coloring

The main manifestation is that the pulp is mature and the hardness meets the requirements, but the skin turns yellow unevenly, the color is not yellow enough, or does not change color.

(1) The ripeness of the picked fruit is not enough, and the solid content is less than 14%, which causes the fruit to not completely change color.

(2) Planting problems, too much nitrogen fertilizer is applied, and chlorophyll conversion is slow during the ripening process.

(3) The shade branch fruit and the inner hall fruit have slightly less color-changing effect than the sunny fruit.

(4) If the ripening temperature is too high, the chlorophyll will decompose during the ripening process, and the peel will turn color. The optimal temperature for color change is 20-22 °C.

(5) If the concentration of carbon dioxide is too high, the color change is actually an oxidation process. The lack of participation of oxygen and the inhibition of carbon dioxide will naturally result in poor color change.

Ripening temperature too high / carbon dioxide concentration too high

Shade branch / inner hall fruit / ripening temperature is too high

Black spots rot

The main manifestations are black spots of corruption, and the stalks become soft and rotten.

(1) Orchard management problems during planting, serious bacterial infection.

(2) Improper post-harvest treatment, no effective sterilization procedure, or cross-infection during the sterilization procedure.

(3) During the ripening process, the ripe mango temperature is too high to accelerate the growth of bacteria, and the optimum pulp temperature is 18-20°C.

(4) During the process of receiving and storing the goods, it is necessary to find out the problematic fruits in time and isolate them.

Spots

There are rash-like reticulate spots on the stomata on the surface of the fruit, brown to black.

(1) It is formed by gum during orchard planting and packaging.

(2) The fruit is not pre-cooled, and ethylene is injected when the pulp temperature exceeds 24°C.

Diffuse brown to black spots

(1) When the fruit is cold, the skin has brown to black spots, and the skin subsides in severe locations, but the inside of the pulp is not affected. The storage temperature must be above 10℃.

(2) The storage period is too long and is affected by low concentration of ethylene, resulting in spots.

If you are a mango grower or processor and want to determine whether the mangoes are damaged or rotten, you can choose our mango color sorting machine. With special technology, it can detect the internal conditions of the mangoes and classify them. It can be customized according to processing needs. If necessary, please feel free to contact us.