The dry fruit processing business plan covers all aspects from fruit selection to drying (problems that may arise during the drying process) to analysis of the benefits of dried mangoes, as well as market sales. As a mango dryer manufacturer, based on our many years of industry experience, we have Some experience summaries of clients who want to do dried mango business.

How to choose mango fruit in dried mango factory?

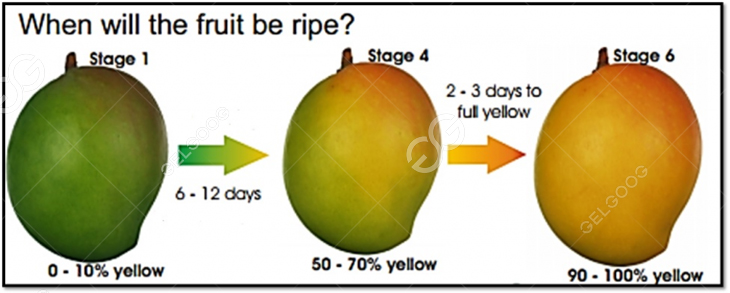

High-quality dried mango processing products must start from the strict selection of fresh fruits. There are many varieties of mangoes in the world. Among them, there is a mango with small stone and small skin, thin skin and thick flesh, so it is often used by locals to make dried mangoes. After years of repeated experiments, we have come to the conclusion that the fresh mangoes used for drying are the best, and the mangoes that are too ripe or too raw will affect the drying taste of the mangoes. The moisture content of dried mango is 15%-18%, the taste is the best, the appearance is also the best, and the preservation effect is also the best.

How to dry mango?

The process from fresh mango to dried mango chips generally takes about 12-15 hours. At present, two drying methods are commonly used on the market, one is natural drying, and the other is drying room. Here I mainly talk about heat pump drying technology, using conventional mango drying machine, using reasonable air duct design to make all dried mango chips evenly heated, the temperature design is 38 degrees, 41 degrees, 43 degrees three stages and three temperatures bake. At the same time, the alternating hot and cold air cycle and dehydration technology are used every 30 minutes to make the dried mango chips more yellow, more transparent, more tender, sweet and sour, sour and fragrant, very chewy and layered feel.

What can go wrong with dehydrating dried mango chips?

Dried mango baking is very particular, and the actual temperature design will be deviated. It will change according to the weather conditions and the sugar content and moisture content of the mango. For example, if the sugar content of the mango is too high, the temperature will be appropriately lowered. , otherwise it will be easy to turn black, the fruit with too high water content, the temperature is too high, it is easy to foam or crack, the temperature is too low, it is easy to bake and so on. In general, the baking pass rate of more than 85% is considered qualified. You can do trial and error based on local fruit varieties.

Dried Mango Chips Benefit Analysis.

One hundred kilograms of fresh mango can yield 10 kilograms of dried mango chips. Now the main producing area of mangoes recycles about one yuan per kilogram in large quantities (the price is often fluctuated). Sometimes mangoes are unsalable and the price is unimaginably low. Dried mango chips can achieve a profit of more than 30%. Because our processing technology is better than that of the general counterparts, the dried mango chips are bright in color, uniform in shape without cracking, and moderate in taste and hardness. Higher profit of 3-5 yuan per catty.

Dried Mango Chips Market sales.

We have a self-operated high-end dried fruit brand in Vietnam and an OEM production route. The taste of dried fruit is the most important. Generally, dried fruit can be put on the market after drying. He said that the taste is the best at this time. In order to maintain the best taste, we recommend customers to use vacuum packaging. It can be extended to more than 6 months, or even longer, which greatly reduces the risk of production and sales. Now our Vietnamese customers are in short supply of dried fruit products. At the same time, we have also undertaken the OEM business of several brands, and have been doing well in the local area.

Since this article will involve a lot of data analysis, dried mango fruit practitioners and friends who are interested in dried fruit processing projects are very welcome to learn, exchange and discuss together. At the same time, this project is also a small investment, low cost, and belongs to the processing of agricultural and sideline products. The certification procedures are very simple. If there are abundant fruit resources in the local area, it is not limited to mangoes, but also peaches, strawberries, bananas, pineapples, etc., the origin of these fruits. friends can also find out.